Categories

Sidebar Product

Flexographic Inks

Flexographic Ink

Your search for fast-drying and sustainable flexographic inks ends here.

DIC India is among the country’s oldest solvent-based and water-based flexo ink manufacturers.

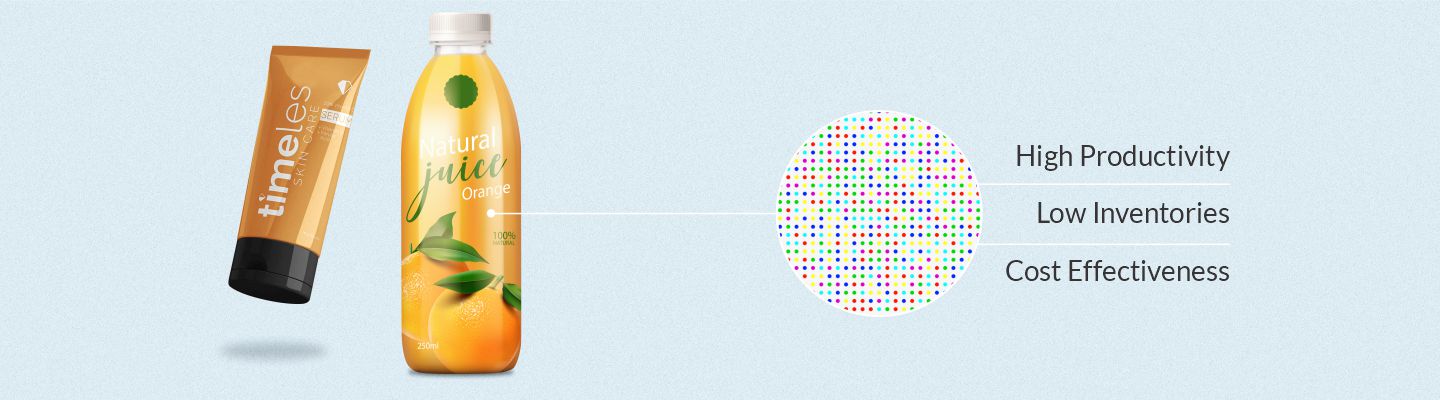

Our range of flexographic inks is designed especially for the fast-growing label and packaging industry. Get an immaculate finish, clear labels, and vibrant colours with our highly pigmented, low-viscosity flexo inks.

High performance topcoats

- Pressure sensitive labels

- Shrink sleeves

- IML

- Tubes printing

- Rotary silk screen

- Self-adhesive labels

The unique technologies offer a great value to the convertors in terms of versatility, cost effectiveness, low inventories, inks recyclability and high productivity .The systems offer huge reduction of raw material components imparting a competitive edge to the printers. We also offer a host of general and special effects coatings, primers for decorative and performance functions.

Solvent Based Flexo Inks Product Range

GPL/ Unolam Inks:

- Highly pigmented

- Low Viscocity

- High transparency

- Tubes printing

- Gloss finish

- Suitable for high printing speeds

SunEster Inks:

- Designed for PE-extrusion lamination

- Low Viscocity

- Excellent bond strength

- Best for HD printing with lower ink GSM

Polytone/Polytone Plus Inks:

- Best for treated LDPE

- Excellent dot reproduction with minimum gain

Sigmafilm and Daiol Resist Inks:

- Low odour, high strength

- Suitable for polyolefin

- Excellent heat resistance

- Resistant to water, oil, milk, and fats

- Good scuff resistance and slip properties

Pinnacle, Pinnacle Plus and Corona Hitone Inks:

- Moderate heat resistance

- Suitable for polyolefin

- High transparency

- Resistant to water, oil, milk, and fats

- Unmatched colour depth

Water Based Flexo Inks Product Range

Corroflex Inks:

- High-strength flexo inks

- Designed for printing on bleached or natural kraft liners, paper, recycled paper, and fibre boards.

- Suited for both line and tone printing

- Water-bleed resistant and deep-freeze resistant once dry

Aquafine Inks:

- High gloss

- Strong adhesion properties

- Free from heavy metals

- Water and alcohol resistant

- Excellent rheology

Aseptic packaging:

- Packaging ink

- Ideal for the beverages sector

Neptune PE Inks:

- Designed for PE-coated paper cup printing

- Also suited for polyethene-coated cups and board tableware

- Good water resistance

- Resistance to condiments and food additives

Neptune Coffee Cup Inks

- Designed for surfaces with a high coefficient of friction

- Resistance to hot and cold beverages

AquaLam SunStrato™

- It is ideal for treated and coated films intended for subsequent lamination

- Provides stable viscosity on press

- Low foaming and fast drying

AquaThene SunSpectro™

- Perfect for printing on treated polyethene films and poly-coated boards.

- Provides stable viscosity on press

- Low foaming and fast drying

UV Cureable Inks:

- Does not contain banned photo-initiators.

- Wide colour gamut

- Excellent rheology

Special Coatings

SunSpectro Matt Finisher: It provides velvety touch / feelings after application. It is available in Matt lacquer for over printing on Treated Bare or Printed LDPE, OPP & PET

Imported 2K OPVs: It has excellent printability along with being chlorine free, it has long pot life. It can be applied over treated PE, Coextruded OPP (plain corona treated), CC PET, Corona treated PA (Nylon) etc.

Corrugation packaging : Complete range of preprint and post print Corroflex ink system with proven technologies of Group companies in Europe.

Label printing : The new UV Flexo range of products caters to the following segments of narrow web industry:

Flexographic Printing Presses required a unique press setup before producing the colourful printed jobs. The process involved mounting the plates on the plate cylinder and pouring the inks in the Ink-ducts.

Since Flexo printing is a direct transfer process of transferring the image on the substrate, which requires the ink properties to be unique and fast-drying.

Being one of the oldest flexographic ink manufacturers in the country and having a broad channel of flexographic ink suppliers in the country, we are proud to share that we have a boutique of water-based flexographic ink formulation to develop the water-based ink for flexo printing.

Flexo water-based inks are in High Demand Due to their sustainable nature. Now, We can proudly say we are one of the coveted water-based flexo ink manufacturers. Solvent-based flexographic ink also holds its own value for being on the economic side during the purchase. Flexo printing has a predominant presence in short-run printing jobs, and we have an in-depth understanding of the need for printers and converters.

Our product portfolio in flexographic printing ink offerings, both Water-based Ink and Solvent-Based Ink, make us one of the finest flexographic printing ink manufacturers in the country.

The water based inks for flexographic printing can make your label printing application sustainable by adding its chemical-free composition USP. Water based Flexo inks contain almost 80% water as Base liquid material during the manufacturing of the water-based flexo printing ink.